Specialized Processes

At CPI, technology and diversification are the keys to our expertise and productivity.

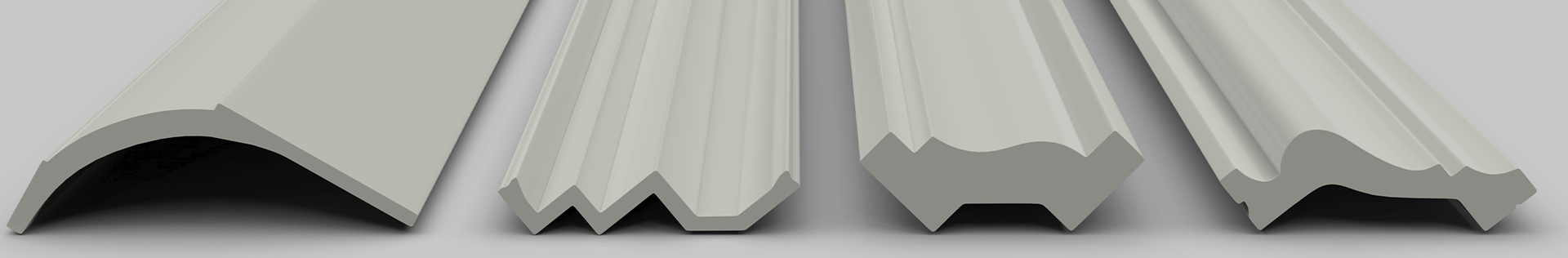

Our dedicated engineers utilize the most up-to-date CAD and EDM tooling manufacturing techniques to make custom extrusion tooling that satisfy even the most demanding specifications. We can also perform a wide variety of value-added processes, including: dual-durometer and tri-extrusion, cross-heading, capstock, printing, embossing, drilling, miter-cutting, tape or adhesive application, and other part-specific fabrication tasks. For large volumes, these operations often can be performed in-line during the extrusion process, which saves on production time and cost. Custom Profiles uses the latest plastic extrusion technology to develop the parts we make and to produce them to exact standards.

If you’re interested in working with Custom Profiles Incorporated for your company’s extruded plastic needs, call 229-423-2929 or contact us online now.

Value-Added Processes During the Plastic Extrusion Process

As mentioned above, there’s a number of value-added processes we can perform during the plastic extrusion process. Here’s more information on what these processes entail:

- Dual-Durometer and Tri-Extrusion: This features multiple materials in one extrusion process.

- Cross Heading: This process helps customize the plastic extrusion process to fit your individual needs.

- Capstock: This special type of resin helps protect anything from decks and windows to pools and golf carts.

- Embossing: We can raise the texture of your product to create a design on it.

- Miter Cutting: A miter cut is an angled cut on top of two structures that allows them to join together and make a corner, or a miter joint.

- And more!

If you would like to know more about our specific value-added processes that can take place during the plastic extrusion process, contact Custom Profiles Incorporated online now or call 229-423-2929 to speak to a member of our team.

Types of Extruded Plastic Materials

Custom Profiles runs a wide range of plastic materials as well. Each material can be as unique as the product into which it is shaped. Some of the Engineering Resins and Specialty Materials extruded at CPI are:

- Noryl® (PPO / PPE)

- Geloy® (ASA)

- Lexan® (Polycarbonate)

- Xenoy® (PC/PBT resins)

- Radel® (Polyethersulfone)

We also extrude General Purpose Plastic Materials like:

- Polyethylene (PE, LDPE, MDPE, HDPE, LLDPE)

- Polypropylene (PP, Homopolymer, Copolymer)

- Polystyrene (HIPS, GPPS, CPS)

- ABS (Acrylonitrile Butadiene Styrene)

- Thermoplastic Rubbers and Elastomers (TPR / TPE)

- Rigid and Flexible vinyl’s (RPVC, FPVC, RV, FV)

- And various blends

Ready to take advantage of this large variety of plastic materials? Call Custom Profiles Incorporated now at 229-423-2929 or contact us online.

Why Choose Custom Profiles Incorporated for Your Extruded Plastic Needs

Custom Profiles Incorporated is not like any other manufacturing company. We understand you have specific, personalized product needs, and we have the plastic extrusion processes to take care of them. A majority of our products are run-to-ship, so we can meet your needs on time, every time. We have worked for the automobile industry, furniture companies, general consumer goods, and so much more. We are the hi-tech thermoplastic extrusion company you can trust for all your needs!

Call 229-423-2929 or contact us online now to talk to a member of our team about how we can help you with your plastic extrusion profile needs today.