Extruded Plastics for Hydroponics

Hydroponics, a method of growing plants without soil, depends on plastic reservoirs to hold the nutrient solution required for plants to grow. As a participant in this industry, you are familiar with the many benefits of hydroponic agriculture, including decreased water usage. This technique provides an option for people to grow their own food in harsh environments with less accessible water.

Most hydroponic reservoirs and siphon tubes are built of plastic. The correct size and shape for your project can only be achieved through plastic extrusion. Custom Profiles is proud to supply custom plastic products for the hydroponics industry. We ship all over the U.S. and internationally to meet the needs of our customers, regardless of their location.

To learn more about extrusion for hydroponics, or to place your order, please contact us at 229-423-2929.

Types of Plastics Used in Hydroponics

Plastics are used extensively in the hydroponics industry. However, if the incorrect type of plastic is used, dangerous chemicals could leach into the water, contaminating the plants and affecting anyone who eats them. Two compounds with the greatest potential to cause cancer or disrupt hormones in humans are bisphenol A (BPA) and phthalates. The key to reducing exposure to these chemicals is to use the correct type of plastic in your hydroponics operation.

Plastics are grouped into seven categories based on their recyclability. The two types deemed safe for use in hydroponics are #2 (high-density polyethylene) and #5 (polypropylene). Both plastics are approved for indoor and greenhouse use, where UV light and weather damage are minimal.

At Custom Profiles, we extrude both of these plastic types to create food-safe reservoirs and siphons for hydroponics operations around the country and across the globe. If you’re not sure what type of plastic is best suited for your precise application, our extrusion experts can help you make the right selection.

How Does Extrusion for Hydroponics Work?

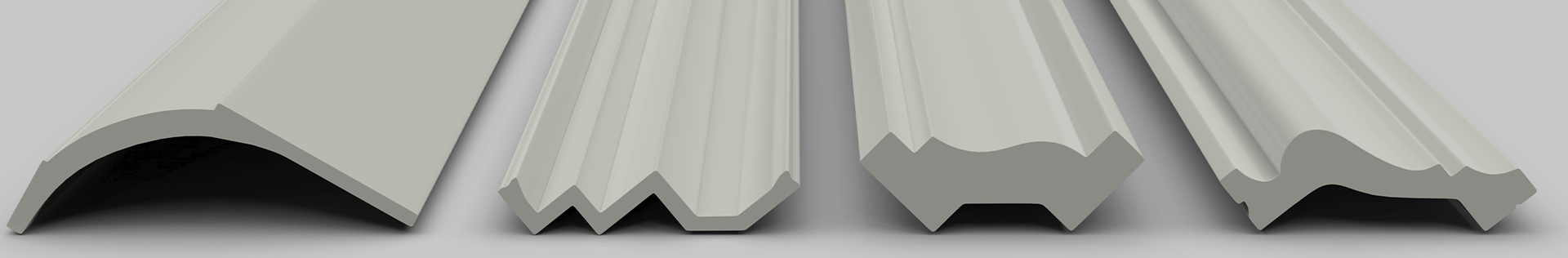

Plastic extrusion is different from sheet production and injection-mold techniques. The process can be confusing at first, but it’s really quite simple once you understand how it works. First, raw plastic material is melted down into a thermoplastic fluid using heat and mechanical shearing. The liquid plastic is then fed through a die opening by applying compressive force. This shapes the plastic and cools it into a solid form.

Our cutting-edge machines and technology allow us to create products with unparalleled precision. No matter what shape you need for your hydroponic reservoirs, our extrusion equipment can handle the task. You are limited only by your imagination and the materials available.

We proudly specialize in custom profile extrusions, which means our engineers design and implement the tools required to produce your specific product. There’s no need to compromise with off-the-shelf stock items when you have access to custom extrusion for hydroponics!

Extruded Plastics from Custom Profiles Inc.

Custom Profiles is a quality-oriented company producing custom plastic parts for numerous industries. We are not a generic supply house providing small quantities of stock items. Instead, our extruded parts are customer- or industry-specific, released in relatively large batches to facilitate extensive or ongoing projects.

Our careful attention to detail ensures that your extruded plastic reservoirs and siphons meet the exact specifications of your hydroponics project. We look forward to working with you soon and fulfilling your order with 100% satisfaction!

Contact Custom Profiles today at 229-423-2929 to learn more about what we do or to inquire about placing an order.