As the mercury starts to rise here in Fitzgerald, Georgia, we at Custom Profiles, Inc. find our thoughts turning to an important consideration for our plastic profile extrusions. This consideration isn’t triggered because these profiles will remain under the Georgia sun, but rather because they embark on a journey worldwide, potentially exposed to the scorching heat of diverse climates and the intensity of various summer suns.

Heat and Plastic Profiles: A Global Consideration

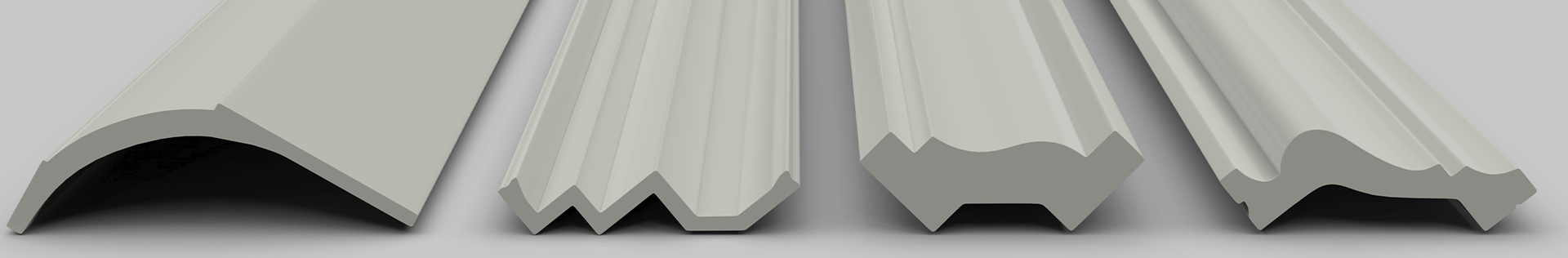

At Custom Profiles, Inc., we proudly provide high-quality plastic profile extrusions to a variety of sectors, from construction and automotive to consumer goods. Our products, crafted here in sunny Fitzgerald, Georgia, find their way across the globe, serving a multitude of applications and industries.

Despite the geographical differences, the intense heat of summer can pose a challenge to these materials. Certain materials, such as Polyvinyl Chloride (PVC), Polyethylene (PE), and Polystyrene (PS), can absorb a significant amount of heat. This can lead to issues such as deformation, discoloration, and a shortened product lifespan, especially during hot summer months when the sun’s rays are at their most intense.

The Importance of Color

Color plays a significant role in how much sunlight – and therefore heat – a material absorbs or reflects. Darker colors tend to absorb more sunlight, which leads to higher heat absorption. On the other hand, lighter colors, like white or beige, reflect more sunlight, which keeps the material cooler.

This principle, well-known to us Georgians, is the same reason we choose lighter-colored clothing in summer to keep cool. At Custom Profiles, Inc., we encourage the same consideration for your plastic profile extrusions. Opting for lighter colors can significantly reduce the risk of heat damage, helping ensure your products can stand up to the summer sun, wherever in the world they may be.

Beyond Color: Heat-Resistant Materials and Additives

Color is a critical factor, but we offer more solutions at Custom Profiles, Inc. to combat heat damage. The choice of material can make a big difference. Plastics like Polypropylene (PP), Polyethylene Terephthalate (PET), and Polycarbonate (PC) are inherently more heat-resistant, making them excellent choices for applications potentially exposed to intense sun.

We also offer UV-resistant additives or coatings. These substances can be incorporated during the extrusion process or applied to the finished product. They enhance the material’s resistance to prolonged sunlight exposure, reducing the risk of heat damage even further.

Partnering with You Against the Heat

As the southern Georgia summer begins to make its presence felt here at Custom Profiles, Inc., it serves as an apt reminder of the considerations we must keep in mind regarding heat exposure for our plastic profile extrusions. We extend this reminder to all our esteemed customers and prospects across the globe: it is crucial to consider the potential exposure of your profiles to sun and heat, no matter their final destination. By making informed decisions about color selection, material choice, and use of UV-resistant additives, we can ensure our plastic profile extrusions remain resilient and effective under the intense summer sun. At Custom Profiles, Inc., we remain committed to helping you make these wise choices, enhancing the longevity and quality of your products. Because, after all, it’s not just us who appreciate a little shade during the summer.